Understanding the Key Parts of a Wind Turbine

Harnessing the power of the wind is an ancient concept, but continues to gain popularity in modern times as an alternative or supplement to power plants that deplete natural resources. Wind energy is renewable, not relying on fuel, and clean – not releasing harmful emissions as it generates electricity. But how exactly do wind turbines work?

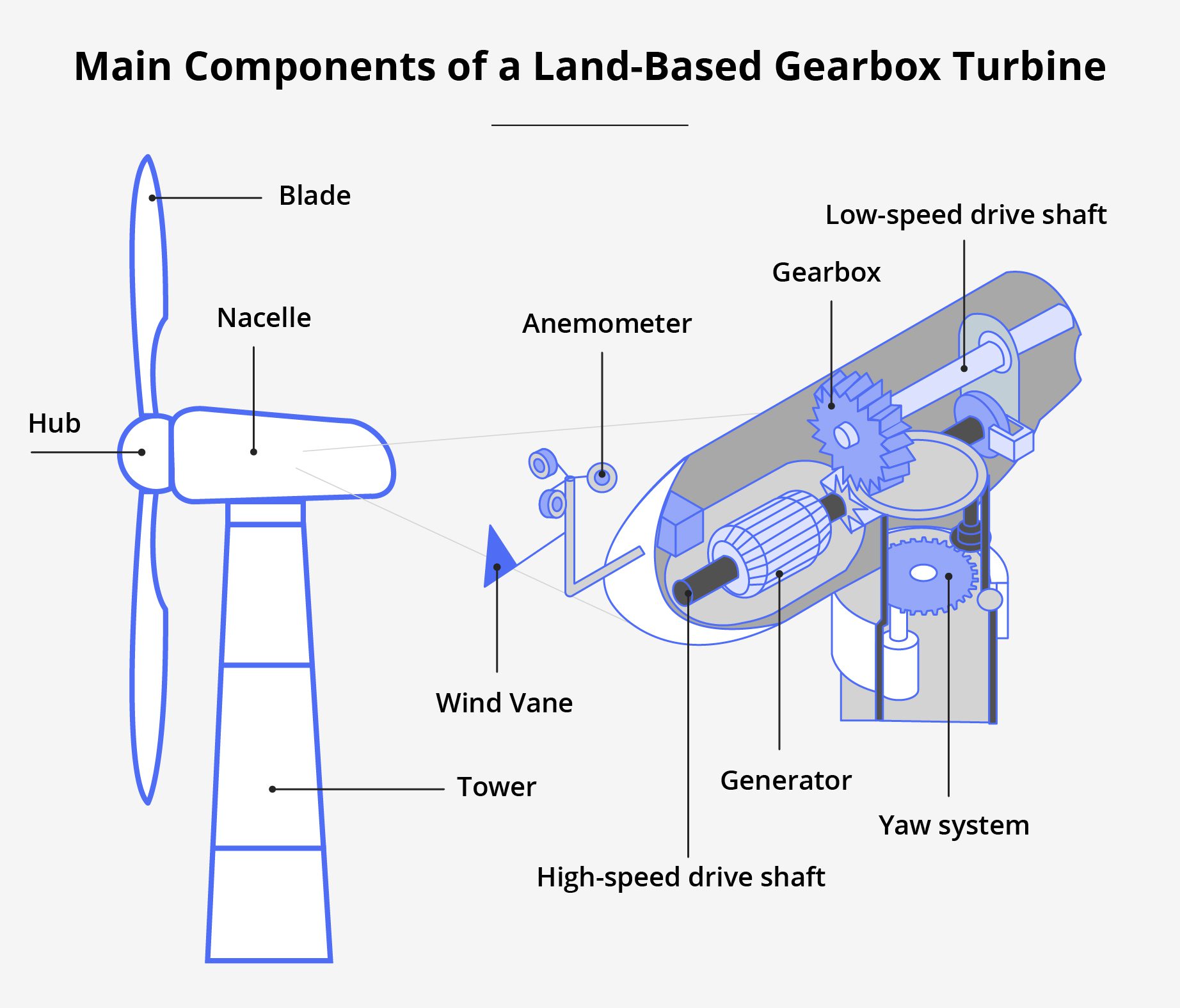

The modern wind turbine is a complex machine, housing several thousand parts – from the massive steel tower to the wind vane and anemometer that sit on top. The main components of a land-based gearbox turbine are the tower, nacelle, hub, yaw system, and the turbine blades. Read on for more information about what these wind turbine parts do (and their massive dimensions) – but keep in mind that wind turbine sizes are only growing as more resources are invested in the wind industry!

Tower

Wind turbine towers reach from the foundation to the nacelle, allowing the rotor to access high wind speeds far above ground level. Turbine towers are made of tubular steel to successfully support the weight of the nacelle, hub, and blades.1 In the United States, utility-scale, onshore wind turbine towers reach an average of over 100 meters (328 feet), particularly in the Midwest and Northeast.2 For this massive section of the turbine to be successfully transported and assembled, the tower is typically manufactured in three sections. A wind construction company will assemble the tower and other major parts on-site at the wind farm, using heavy-duty cranes.

What is a rotor?

The rotor is a collective term for the rotating components of a wind turbine, namely the hub and blades. You may see the terms ``rotor hub`` or ``rotor blades,`` which are just alternative titles.

Nacelle

The nacelle houses the mechanical components needed to convert the rotation of the turbine blades into energy – also known as the drivetrain. From a distance, the nacelle may seem like a relatively small section of a wind turbine, especially when compared to the tower and turbine blades. However, this part of a wind turbine can weigh over 50 tons (100,000 lbs).3 Transporting nacelles requires special equipment for supersize loads, as normal flatbed trailers do not have the capacity to handle that weight.

A few of the most notable components inside the nacelle are the gearbox, the generator, and the drive shaft:

Gearbox

The gearbox helps to convert the relatively slow rotational speed of the turbine rotor to the high speeds needed to run the generator. The rotor achieves around 18 revolutions per minute (rpm), while the generator will need around 1,800 rpm to successfully generate electricity.4 The gearbox connects the rotor hub to the generator by a series of drive shafts.

Drive Shafts

The turbine’s drive shafts are integral parts of the drivetrain, working in conjunction with the gearbox to increase rpm and run the generator. The low-speed shaft (also known as the main shaft) connects the hub to the gearbox. A smaller, high-speed shaft connects the gearbox to the generator.

Generator

The generator is ultimately what converts wind power to electrical energy by means of electromagnetic induction. Wind energy is an increasingly popular renewable energy source because it does not require mining or digging for fossil fuels, instead running on an endless supply of kinetic energy provided by the wind. It’s also a “clean” form of energy that doesn’t burn fossil fuels or release carbon emissions.

Check out our guide to learn more about the Advantages of Wind Energy

Hub

The hub is part of the rotor, securing the three blades and connecting them to the drive shaft in the nacelle. The hub has a cast iron structure weighing between 7 and 14 tons (14,000-28,000 lbs), as it needs to be sturdy enough to support the weight of the turbine blades.5 Wind turbine hubs have an average length of 4-6 meters (13-20 feet), and a diameter of 3-4 meters (10-13 feet).6 Wind turbines are often measured in terms of “hub height,” which refers to the distance from the ground to the center of the hub.

Yaw System

The yaw system underneath the nacelle is responsible for orienting the turbine according to wind direction (determined by the wind vane and anemometer). The yaw drive and yaw motor work together to adjust the nacelle so it captures wind power as effectively as possible. This system is crucial for maximizing the value of the turbine and keeping the generator running at a more constant rate.

Blades

Blades for onshore, utility-scale turbines in the U.S. average between 200-300 feet long – and they’re consistently being manufactured at larger sizes to achieve a higher power output. Turbine blades are adjusted by the “pitch system,” which is based on wind speeds. The pitch system helps turn the rotor at an optimum speed – ensuring that high winds that are too strong don’t damage the turbine.

Modern turbine blades are primarily made of aerodynamic fiberglass and are hollow. These factors make turbine blades lighter than the steel tower and even the nacelle – but they still weigh several tons at least, and their sheer size poses significant logistical challenges.

Transporting wind turbine blades is a complicated process. These supersized loads require route planning far in advance – to coordinate escorts, road shut-downs, and to make sure the truck can successfully navigate narrow roads and bridges. Safe and timely delivery will also involve special flatbed trailers, permits, and driver expertise.

Dimensions of Wind Turbine Parts

The dimensions of wind turbine parts range drastically between small residential models and enormous offshore wind turbines. In July 2023, China installed the world’s largest offshore turbine, a 16-MW machine over 500 feet tall – with individual blades measuring 400 feet each.7

To better understand the dimensions of wind turbine components relative to the turbine’s power capacity, consider the below specifications of a land-based GE 1.5xle turbine.8 GE is a major global player in the wind energy industry, having installed upwards of 49,000 onshore wind turbines in 35 countries.9 GE’s 1.5 MW wind turbines are common models of land-based, utility-scale turbines.

GE 1.5xle Wind Turbine (2005)

Land-Based

Power Capacity: 1.5 MW (1,500 kW)

Rotor Diameter: 82.5 meters (271 feet)

Nacelle Weight: 54 tons

Rotor + Hub: 31 tons

Hub Height*: 59-100 meters (194-328 feet)

* measured from the ground to the center of the hub

Source: https://www.thewindpower.net/turbine_en_58_ge-energy_1.5xle.php

Wind Turbine Manufacturing and Transportation

While turbine components are predominantly manufactured outside of the U.S. and shipped here from overseas, energy.gov reports that 80% of nacelle assembly is domestic, as well as 70% of tower manufacturing (for turbines installed in the U.S.).10 Wind is steadily gaining popularity as a renewable energy source worthy of domestic investment. There are currently 500 active wind-related manufacturing facilities across the U.S.11

In addition to job creation, domestic turbine manufacturers simplify wind energy supply chains – an important consideration as turbine sizes increase, making them more difficult to ship.12 Domestic manufacturing also has environmental benefits, as carbon emissions from wind turbines are due almost entirely to the turbine’s long supply chain.

Once the turbine parts are available at a port or manufacturing facility, the easiest form of inland transportation is by truck – using specialized flatbed trailers that can handle supersized loads. Transporting wind turbine parts via truck requires significant logistics planning done far in advance. Anyone involved in coordinating wind projects will want the assistance of a logistics company with expert knowledge of heavy haul transportation, so your wind turbines arrive at their destination safely and on time.

Planning a wind project? Titan's heavy haul services include expert route planning and transportation for wind turbines.

(1) https://www.energy.gov/eere/wind/how-wind-turbine-works-text-version

(2) https://www.energy.gov/eere/articles/wind-turbines-bigger-better

(3) https://www.wind-watch.org/faq-size.php

(4) https://www.energy.gov/articles/how-wind-turbine-works

(5) https://www.nrel.gov/docs/fy23osti/84438.pdf

(6) https://www.iflscience.com/the-worlds-largest-wind-turbine-has-been-switched-on-70047

(7) https://www.thewindpower.net/turbine_en_58_ge-energy_1.5xle.php

(8) https://www.ge.com/renewableenergy/wind-energy/onshore-wind

(9) https://www.energy.gov/eere/wind/wind-manufacturing-and-supply-chain