Sizes of Utility-Scale Wind Turbines

Wind turbines range drastically in size – from residential models found in backyards to massive, offshore machines that harness ocean winds at high altitudes. The largest wind turbine in the world was installed offshore in China in July 2023. The 16 MW (megawatt) machine is over 500 feet tall, and the individual blades measure 400 feet each – covering a swept area of almost 540,000 square feet.1 Due to the expansive space and near-constant winds over the ocean, offshore turbines are the largest models available.

In the United States, most wind power comes from utility-scale, onshore, horizontal-axis wind turbines. Although turbines are found in regions all across the U.S., wind farms are primarily concentrated in the Great Plains and Great Lakes regions which have abundant wind resources. Current land-based turbines in America have power capacities typically ranging between 1 and 3 MW, but wind turbines only continue to grow in power and size with continued investment in wind as a renewable energy source.

What is the Benefit of Bigger Wind Turbines?

Modern wind turbine designs feature many innovations, such as higher percentages of recyclable materials and better noise suppression. But why do they continue to increase in size? Ultimately, it makes economic sense to continue to engineer increasingly large turbines. Taller wind turbines are able to capture winds at higher altitudes and support long blades that sweep a broader area. This results in an increased capacity factor (power output compared to maximum power capacity), and reduced dependence on high wind speeds.

Larger turbines are also more cost-effective than smaller turbines, making more efficient use of the resources it takes to manufacture, transport, and install wind farms. Turbines with higher power capacities take up more space per turbine than a smaller turbine, but require fewer total machines to achieve a higher power output, resulting in a more efficient use of land.

Average Dimensions of U.S. Land-Based Turbines

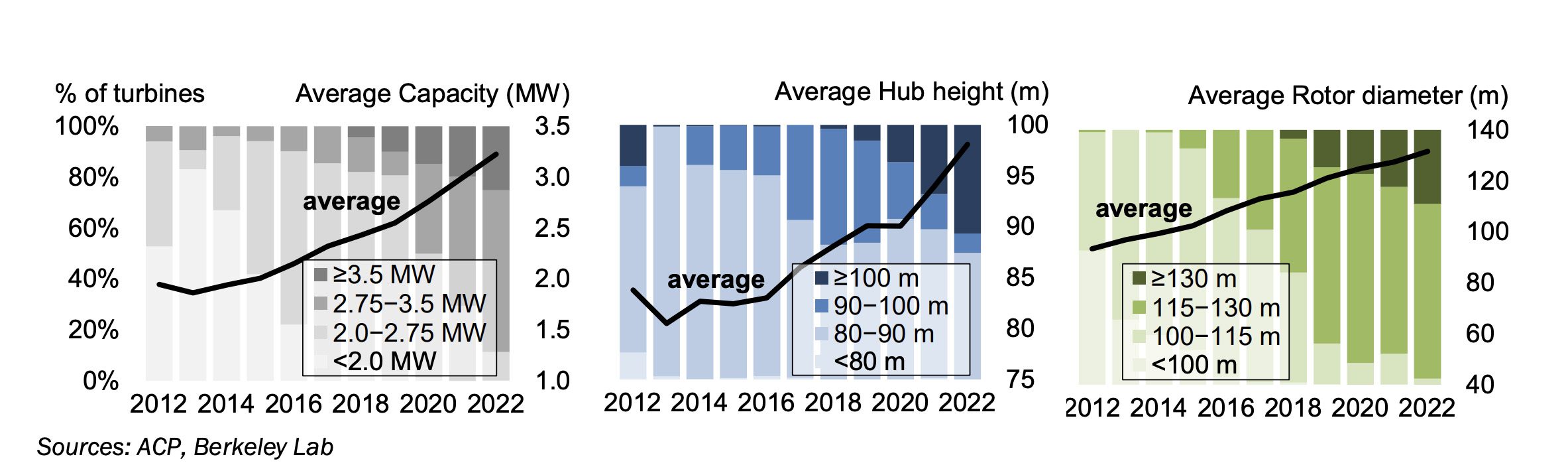

New turbines installed during 2022 in the U.S. have an average power capacity of 3.2 MW.2 Turbine sizes have risen to accomplish higher power capacities over the years, as evidenced in the below chart provided by the U.S. Department of Energy’s (DOE) 2023 Land-Based Wind Market Report.3 Keep in mind that the dimensions considered here do not apply to offshore wind turbines, which are significantly larger turbines than land-based models.

Wind Turbine Height

“Hub height” is the typical measurement for how tall a wind turbine is – measured from the bottom of the wind turbine to the center of the hub. The hub is the part of the rotor that connects the three wind turbine blades to each other and to the nacelle. The average hub height of land-based turbines in the U.S. has risen considerably even over the last few years, from around 80-85 meters (262-279 ft.) in 2012-2018 to 100 meters (328 ft.) in 2022.

Due to their height and weight, wind turbine towers are typically manufactured and transported in three sections and assembled on-site. The tower is made of tubular steel, and even on a relatively small 1.5 MW turbine, has a total weight upwards of 70 tons.4

Hub and Blades

The rotating parts of a wind turbine (the blades and the hub) are referred to as the “rotor.” The average rotor diameter of wind turbines in 2022 was over 130 meters (427 feet) – roughly 100 feet bigger than the average size just a few years ago. Rotor blades individually measure over 200 feet long. Turbine blades are made of fiberglass and are hollow, making them relatively light compared to the steel tower, but they still weigh at least several tons each.5

The hub has a cast iron structure weighing between 7 and 14 tons because it needs to be sturdy enough to support the weight and rotation of the turbine blades. These are the average dimensions of hubs for land-based wind turbines:6

- Weight: 7-14 tons

- Length: 4-6 meters (13-20 feet)

- Diameter: 3-4 meters (10-13 feet)

Nacelle

The nacelle houses the generator, gearbox, and other key components of the turbine’s drive train. It sits on top of the tower and is connected to the rotor. The nacelle may not appear like a large section of the wind turbine when compared to the staggering length of the blades and height of the tower. However, this part of the turbine weighs upwards of 50 tons on a 1.5 MW turbine, and far more on larger models.7

The dimensions of a nacelle will vary widely depending on the model. Here are the specifications of the nacelle on a 4.2 MW turbine manufactured by Vestas:8

- Length: 12.8 meters (42 feet)

- Width: 4.2 meters (14 feet)

- Height: 3.4 meters (11 feet)

Learn more about wind turbine components in our guide to Understanding the Key Parts of a Wind Turbine

Recent Wind Turbine Models

The exact dimensions of any utility-scale wind turbine will need to be provided by the manufacturer of the specific model. GE and Vestas manufacture the most wind turbines for wind farms in the United States – the DOE reports that of the 8.5 GW of wind energy installed in the U.S. in 2022, 58% was supplied by GE Wind and 24% by Vestas.9 Nordex and Siemens are two other major names in wind energy manufacturing, but each supplied only 10% or less of U.S. wind energy in 2022.10

To better understand the correlation between power capacity and the dimensions of wind turbine parts, consider the two types of wind turbine models below and their specifications:

GE 3.4-140

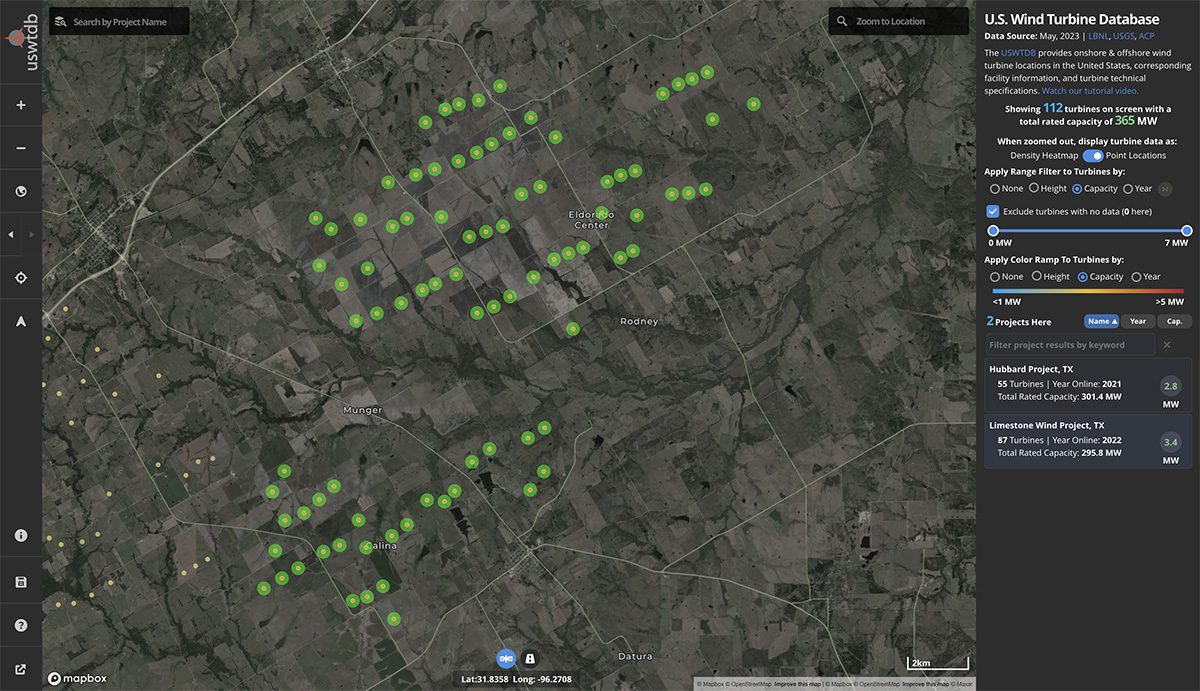

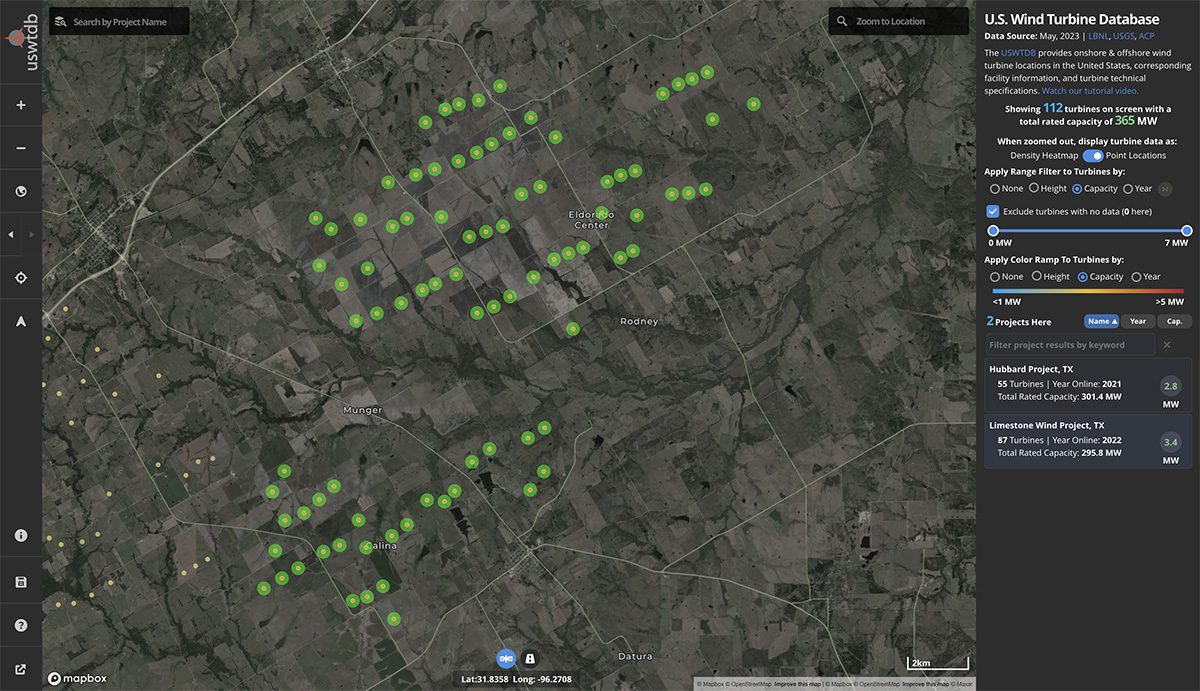

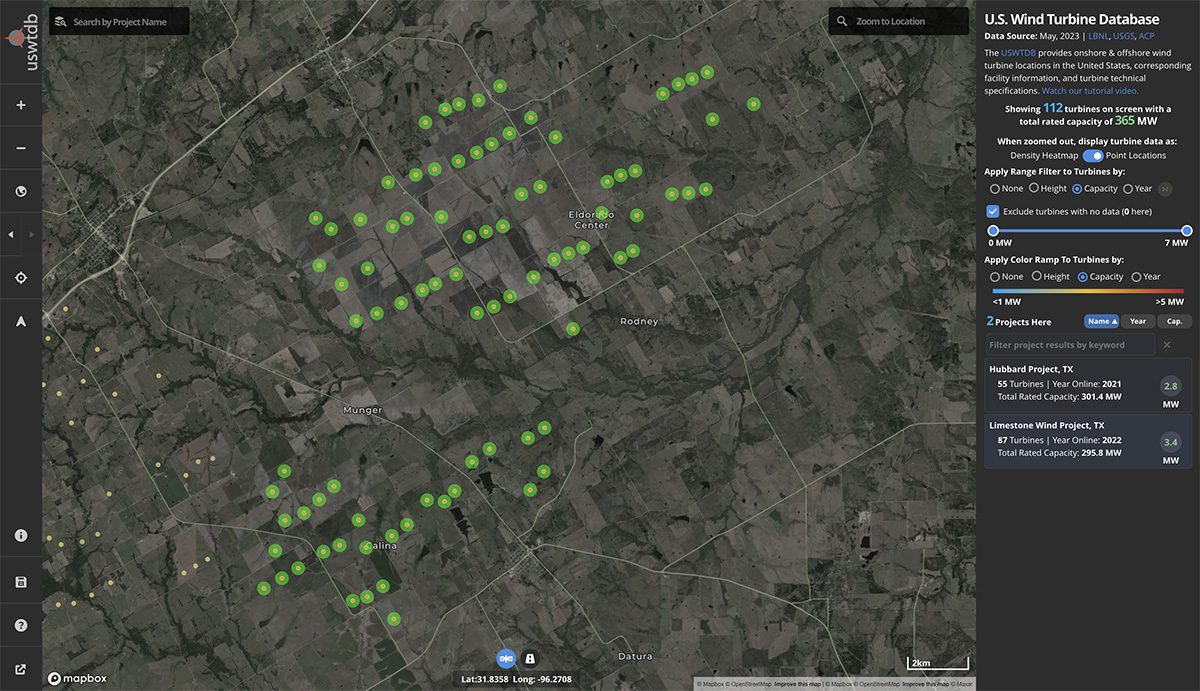

GE’s Sierra Wind Platform, introduced in 2022, features 3 MW wind turbines designed for North American wind farms.11 For improved logistics and installation, GE engineered this product line with two-piece blades. The Limestone Wind Project in Texas features 88 of GE’s 3.4 MW turbines, generating 200,000 MWh of electricity.12

- Power Capacity: 3.4 MW

- Rotor Diameter: 140 meters (459 feet)

- Blade Length: 68.7 meters (225 feet)

- Hub Height: 117 meters (383 feet)

U.S. Wind Turbine Database highlighting the Limestone Wind Project in Texas13

Vestas V150-4.2 MW™

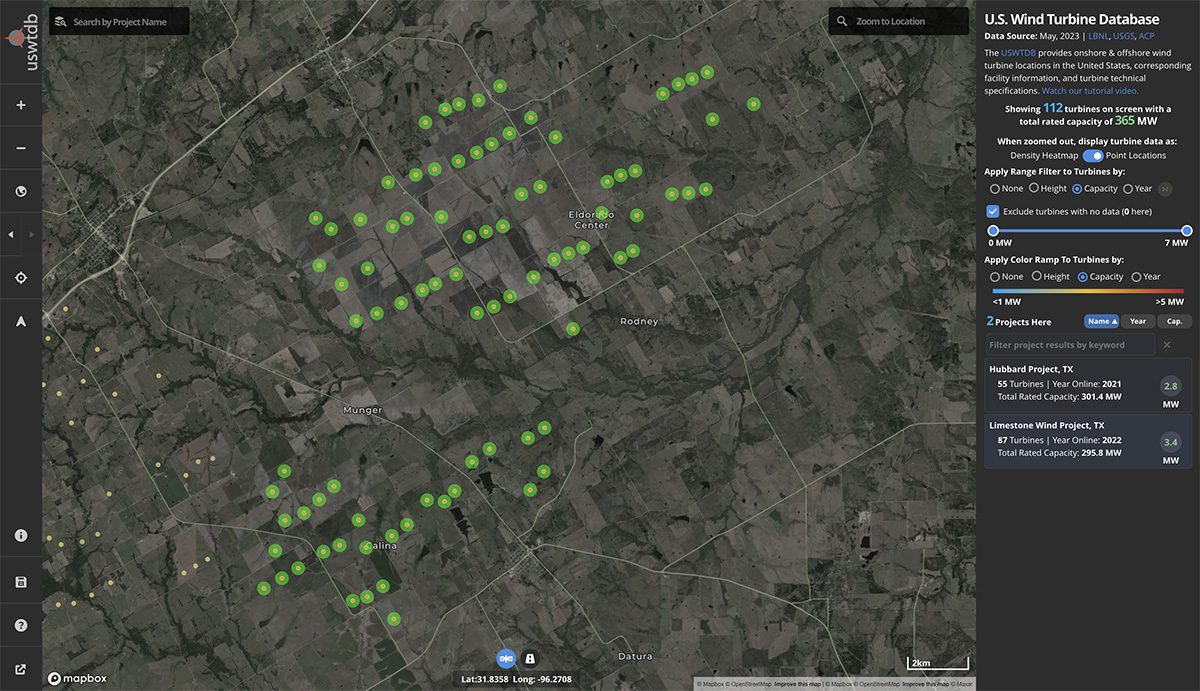

Vestas’ line of 4.2 MW wind turbines are high-capacity machines optimal for significant electricity generation in environments with low wind speeds.14 Here are the dimensions of the V150-4.2 MW turbines installed in Oklahoma as part of the 25-Mile Creek Wind Project. This wind farm is expected to be operational in 2023 and features 60 turbines with a total wind capacity of 250 MW.15

- Power Capacity: 4.2 MW

- Rotor Diameter: 150 meters (492 feet)

- Blade Length: 73.7 meters (242 feet)

- Hub Height: 105 meters (344 feet)

U.S. Wind Turbine Database highlighting the 25-Mile Creek Wind Project in Oklahoma16

Expected Growth of Wind Turbine Sizes

Wind is a renewable and clean energy source – making it an increasingly popular supplement to power plants that burn fossil fuels and release harmful emissions. As the wind industry grows in the United States, wind turbine sizes will increase to accommodate greater power generation. This is especially true for offshore wind farms that capture strong winds over the ocean. Turbine designs can only incorporate sizes that are feasible to transport with available methods, but there has been a steady upward trend in turbine dimensions that we can expect to continue for the foreseeable future.

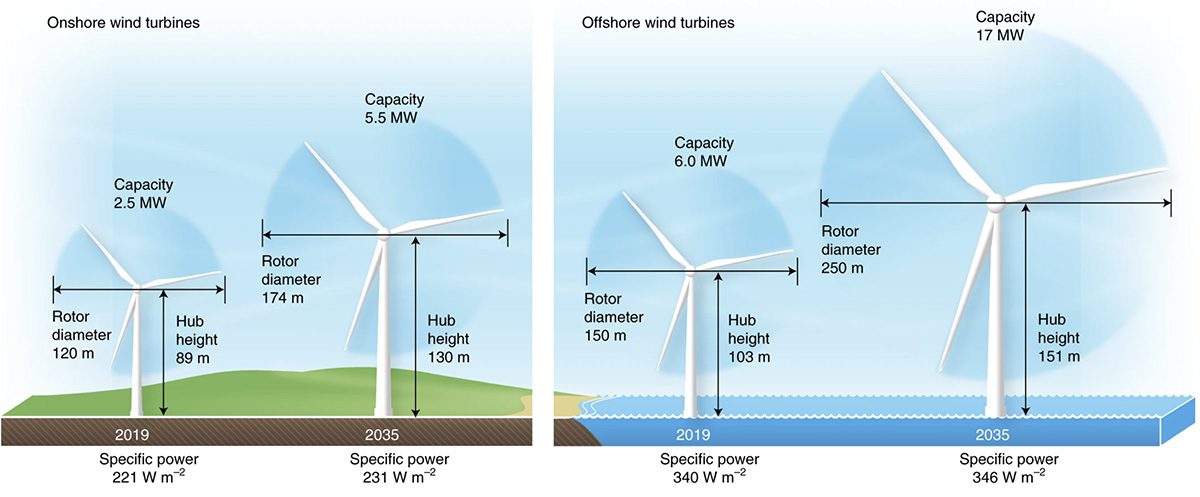

According to the findings of a survey published in Nature Energy, wind energy experts anticipate that onshore wind turbines will reach an average power capacity of 5.5 MW by 2035.17 This significant power capacity would be accomplished by turbines with average hub heights of 130 meters (427 feet) and rotor diameters spanning 174 meters (571 feet). Predictions for ocean turbines feature more drastic sizes, as the U.S. continues to invest in powerful, offshore wind energy.

How are wind turbines transported?

The size of utility-scale wind turbines creates a challenging task for logistics and transportation. The largest parts of a wind turbine (the tower sections and blades) require a number of unique accommodations such as specialized flatbed trailers and permits for supersized loads. Route planning is also done far in advance to ensure the trucks can safely make it through narrow roads, bridges, and other challenging terrain. This endeavor may require escort services and even road shut-downs.

Coordinating a successful wind project requires a significant amount of forethought and a trustworthy logistics partner who can make sure each part arrives at the job site safely and on time – no matter the size.

Planning a wind project? Titan's heavy haul services include expert route planning and transportation for wind turbines.

Endnotes

1. https://www.iflscience.com/the-worlds-largest-wind-turbine-has-been-switched-on-70047

2. https://www.energy.gov/eere/articles/wind-turbines-bigger-better

3. https://www.energy.gov/sites/default/files/2023-08/land-based-wind-market-report-2023-edition.pdf

4. https://www.wind-watch.org/faq-size.php

5. https://www.nrel.gov/docs/fy23osti/84438.pdf

6. https://www.nrel.gov/docs/fy23osti/84438.pdf

7. https://www.wind-watch.org/faq-size.php

8. https://us.vestas.com/en-us/products/4-mw-platform/V150-4-2-MW

9. https://www.energy.gov/sites/default/files/2023-08/land-based-wind-market-report-2023-edition.pdf

10. https://www.energy.gov/sites/default/files/2023-08/land-based-wind-market-report-2023-edition.pdf

11. https://www.ge.com/renewableenergy/wind-onshore/sierra-platform/

12. https://www.power-technology.com/marketdata/power-plant-profile-limestone-wind-farm-us-2/

13. Map services and data are available from U.S. Wind Turbine Database, provided by the U.S. Geological Survey, American Clean Power Association, and Lawrence Berkeley National Laboratory via https://eerscmap.usgs.gov/uswtdb/viewer/#11.71/31.8075/-96.6082.

14. https://us.vestas.com/en-us/products/4-mw-platform/V150-4-2-MW

15. https://www.power-technology.com/data-insights/power-plant-profile-25-mile-creek-us/

16. Map services and data are available from U.S. Wind Turbine Database, provided by the U.S. Geological Survey, American Clean Power Association, and Lawrence Berkeley National Laboratory via https://eerscmap.usgs.gov/uswtdb/viewer/#11.6/36.473/-99.7783

17. Wiser, R., Rand, J., Seel, J. et al. Expert elicitation survey predicts 37% to 49% declines in wind energy costs by 2050. Nat Energy 6, 555–565 (2021). https://doi.org/10.1038/s41560-021-00810-z